How To Charge A Lead Acid Battery

Dependable performance and long service life of your sealed lead acid battery will depend upon correct battery charging. Following incorrect charging procedures or using inadequate charging equipment can result in decreased battery life and/or poor battery performance. The selection of a suitable SLA battery charger and the methods used to charge it is just as important as choosing the right battery for the application.

Power Sonic recommends you select a charger designed for the chemistry of your battery. This means we recommend using a sealed lead acid battery charger, like the the A-C series of SLA chargers from Power Sonic, when charging a sealed lead acid battery.

BATTERY CHARGING TECHNIQUES

- Constant Voltage

- Constant Current

- Taper Current

- Two Step Constant Voltage

To obtain maximum battery service life and capacity, along with acceptable recharge time and economy, constant voltage-current limited charging is best.

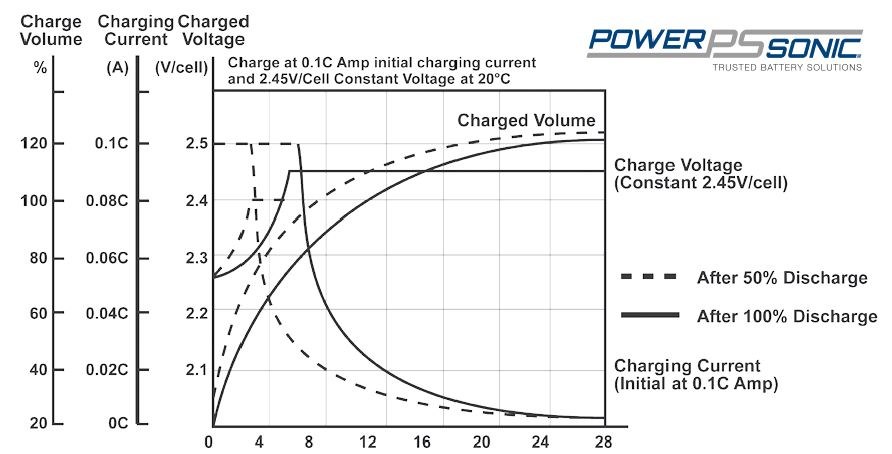

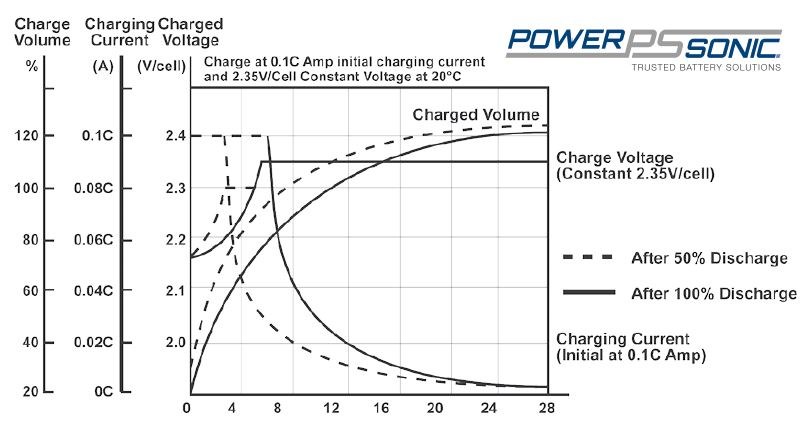

To charge a sealed lead acid battery, apply a DC voltage between 2.30 volts per cell (float) and 2.45 volts per cell (fast) to the terminals of the battery. Depending on the state of charge (SoC), the cell may temporarily be lower after discharge than the applied voltage. After some time, however, it should level off.

During charge, the lead sulfate of the positive plate becomes lead dioxide. As the battery reaches full charge, the positive plate begins generating dioxide causing a sudden rise in voltage due to decreasing internal resistance. A constant voltage charge, therefore, allows detection of this voltage increase and thus control of the current charge amount.

BATTERY CHARGING CHARACTERISTICS

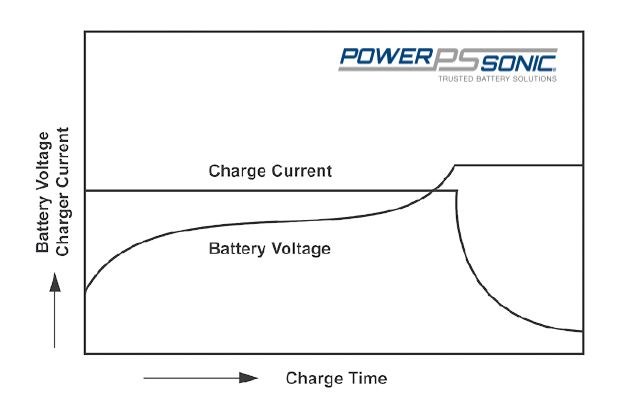

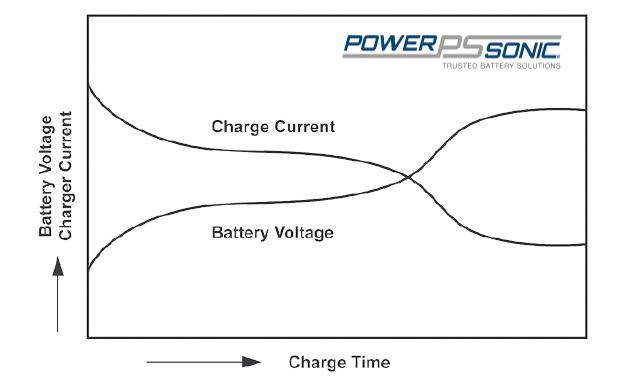

During constant voltage or taper charging, the battery’s current acceptance decreases as voltage and state of charge increase. The battery reaches full charge when the current stabilizes at a low level for several hours. You determine full charge by two criteria: (1) the final current level and (2) the peak charging voltage during this current flow.

BATTERY CHARGING METHODS

Selecting the appropriate charging method for your sealed lead acid battery depends on the intended use (cyclic or float service), economic considerations, recharge time, anticipated frequency and depth of discharge (DoD), and expected service life. The goal of any charging method is to control the charge current at the end of the charge.

CONSTANT VOLTAGE CHARGING

This method best charges sealed lead acid batteries. Depending on the application, you can charge batteries continuously or intermittently. For standby power applications, such as security systems or UPS units, continuous float charging ensures operation during AC power interruptions. For portable equipment, like electric wheelchairs or mobile medical carts, intermittent cyclic charging is appropriate.

The constant voltage charge method applies a constant voltage to the battery and limits the initial charge current. It is necessary to set the charge voltage according to specified charge and temperature characteristics. Inaccurate voltage settings can cause either over-charge or under-charge. This charging method works for both cyclic and standby applications.

CONSTANT CURRENT CHARGING

This method suits applications where the discharged ampere-hours from the previous cycle are known. It allows easy calculation of charge time and quantity, but requires an expensive circuit for precise constant current. You must monitor charge voltage or limit charge time to prevent overcharging.

While effective for restoring SLA batteries stored long-term or for occasional equalization of cell capacities, this method lacks the precision needed for today’s electronic applications.

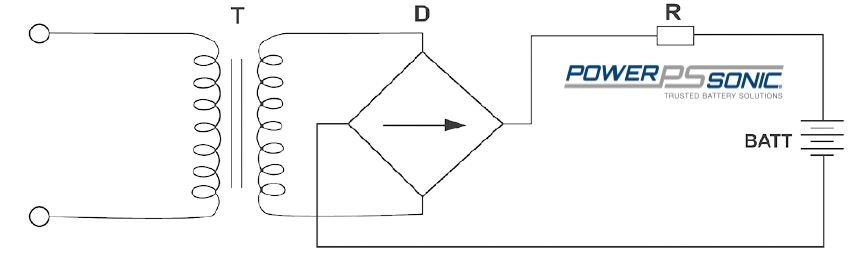

TAPER CURRENT CHARGING

Taper current charging can shorten SLA battery life and is generally not recommended. However, its simple, low-cost design makes it widely used for charging multiple batteries or for cyclic applications.

When using a taper current charger, limit charging time or include a cut-off circuit to prevent overcharge. In this method, current decreases as voltage rises. Designers must account for power voltage fluctuations, as internal resistance converts excess energy into heat. If necessary, include a heat sink to manage the generated heat.

OVERCHARGING A LEAD ACID BATTERY

As a result of too high a charge voltage excessive current will flow into the battery, after reaching full charge, causing decomposition of water in the electrolyte and premature aging.

At high rates of overcharge a battery will progressively heat up. As it gets hotter, it will accept more current, heating up even further. This is called thermal runaway and it can destroy a battery in as little as a few hours.

UNDERCHARGING A LEAD ACID BATTERY

If you apply too low a charge voltage, current flow stops before fully charging the battery, leaving lead sulfate on the electrodes and reducing capacity over time.

Batteries stored in a discharged state or left on the shelf too long may appear “open-circuited” or accept far less current than normal due to sulfation. In this case, keep the charger connected. Typically, the battery gradually accepts more current until it reaches a normal level. If it does not respond, even to higher-than-recommended charge voltages, the battery has likely been discharged too long to recover and will need replacement.

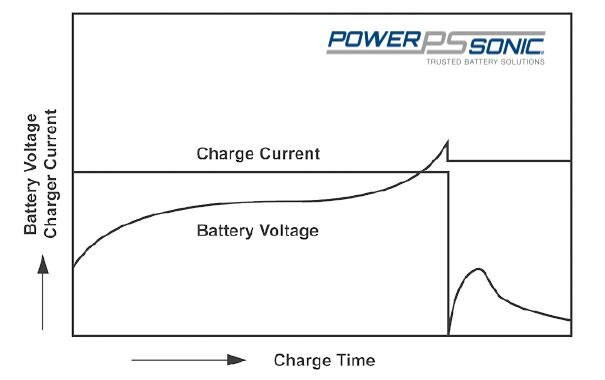

LEAD ACID BATTERY CYCLE CHARGING

In cyclic applications, batteries require rapid recharging, but the initial charge current must not exceed 0.3 × C amps. As the battery charges, its voltage gradually rises. The battery is fully charged when the voltage reaches 2.45 ± 0.05 volts per cell and the current drops below 0.01 × C amps (1% of rated capacity). At this point, disconnect the charger or switch to a float voltage of 2.25–2.30 volts per cell, ensuring the voltage never exceeds 2.45 ± 0.05 volts per cell.

LEAD ACID BATTERY STANDBY CHARGING

In standby applications, batteries do not require fast or frequent charging like in cyclic operation. However, the charger must constantly replace the energy lost to internal self-discharge and natural deterioration. Although Power-Sonic lead acid batteries have very low self-discharge, the charger must match the loss rate to avoid overcharging. To achieve this, a constant-voltage method called standby or float charging is used.

The recommended constant float voltage is 2.25 – 2.30 volts per cell. Maintaining this float voltage will allow the battery to define its own current level and remain fully charged without having to disconnect the charger from the battery. The trickle current for a fully charged battery floating at the recommended charge voltage will typically hover around the 0.001C rate (7mA for a 7AH battery, for example.)

The float charger is basically a constant voltage power supply. As with cycle chargers, care must be taken not to exceed the initial charge current of 0.30 x C amperes.

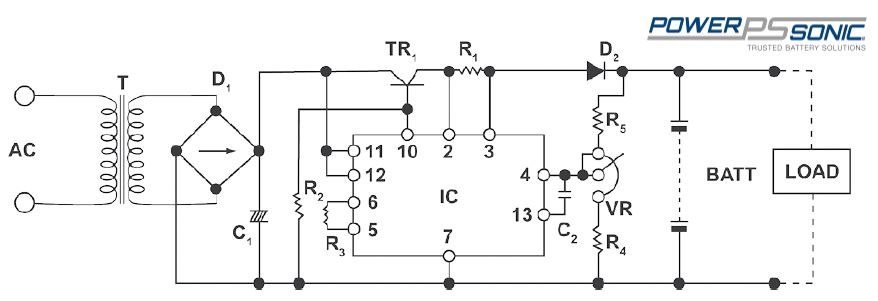

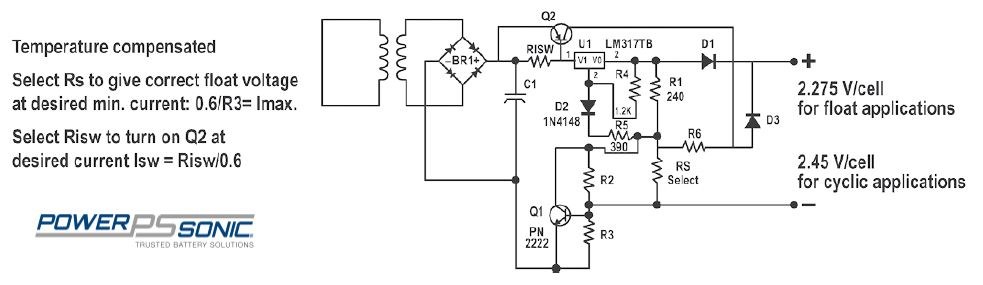

TWO STEP CONSTANT VOLTAGE CHARGING

This method uses two constant voltage devices. In the initial charge phase the high voltage setting is used. When charging is nearly complete and the charge voltage has risen to a specified value (with the charge current decreased), the charger switches the voltage to the lower setting. This method allows rapid charging in cycle or float service without the possibility of overcharging, even after extended charging periods.

CHARGING 2 OR MORE BATTERIES IN SERIES

Lead acid batteries consist of 2-volt cells connected in series, typically 2, 3, 4, or 6 cells per battery. You can safely and efficiently charge battery strings in series up to 48 volts or higher. However, as the series length increases, slight differences in capacity may appear due to age, storage history, temperature, or abuse.

Never mix fully charged batteries with discharged ones in a series string; charge discharged batteries first. When a single constant-voltage charger powers a high-voltage string, the same current flows through all cells. Depending on the characteristics of the individual batteries, some may overcharge while others remain in a slightly undercharged condition.

To minimize the effects of individual battery differences, use batteries of the same age, manufacturer, amp hour, and history and, if possible, charge in strings of no greater than 24 or 48 volts.

CHARGING BATTERIES IN PARALLEL

Lead acid batteries can connect in parallel with one or more batteries of equal voltage, and the charger current generally divides equally. Special matching is unnecessary. If batteries have unequal capacities, the current splits according to their capacities or internal resistances. When charging batteries of different capacities in parallel, ensure the current differences remain minimal.

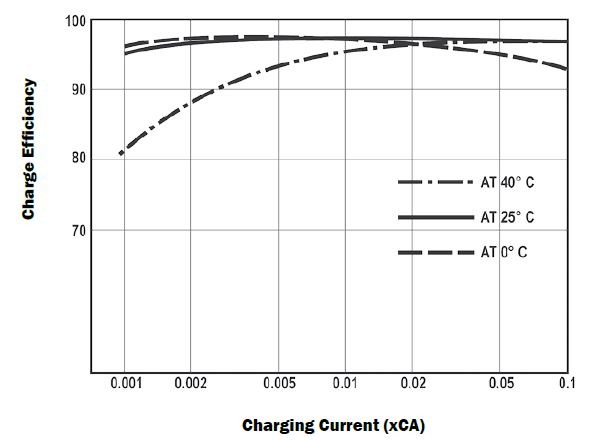

BATTERY TEMPERATURE COMPENSATION

Power-Sonic sealed lead acid batteries perform well both at low and high temperatures. At low temperatures, charging efficiency drops, while above 45°C (113°F), efficiency rises rapidly, creating a risk of thermal runaway if temperature compensation is inaccurate. Temperature impacts are less critical in float applications but crucial in cyclic use with high charge currents for fast recharging. Therefore, always consider temperature effects when designing or selecting a charging system.

Temperature compensation is desirable in the charging circuit, especially when operating outside the range of 5°C to 35°C

(41°F to 95°F). The temperature coefficient is -2mV/cell/ºC below 20°C (68°F) in float use and -6mV/cell/ ºC below 20°C in cyclic use. For higher temperatures the charge voltage should be correspondingly decreased.

The battery temperature compensation chart below shows the recommended charge voltages for different temperatures based on ambient charge voltage per cell.

| Temperature | Cyclic Use (V) | Float Use (V) |

| -40°C (-40°F) | 2.85 – 2.95 | 2.38 – 2.43 |

| -20°C (-4°F) | 2.67 – 2.77 | 2.34 – 2.39 |

| -10°C (14°F) | 2.61 – 2.71 | 2.32 – 2.37 |

| 0°C (32°F) | 2.55 – 2.65 | 2.30 – 2.35 |

| 10°C (50°F) | 2.49 – 2.59 | 2.28 – 2.33 |

| 20°C (68°F) | 2.43 – 2.53 | 2.26 – 2.31 |

| 25°C (77°F) | 2.40 – 2.50 | 2.25 – 2.30 |

| 30°C (86°F) | 2.37 – 2.47 | 2.24 – 2.29 |

| 40°C (104°F) | 2.31 – 2.41 | 2.22 – 2.27 |

| 50°C (122°F) | 2.25 – 2.35 | 2.20 – 2.25 |

TOP UP CHARGING SLA BATTERIES

All batteries lose capacity through self-discharge, so apply a “top-up charge” to any battery stored for a long period before putting it into service.

To successfully top up charge a battery stored for more than 12 months, the open circuit voltage must be higher than 2.0 volts per cell, in this case, always confirm open circuit voltage prior to attempting top up charging.

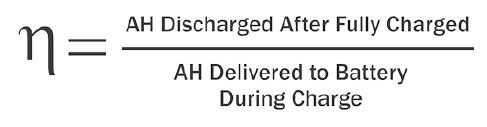

BATTERY CHARGING EFFICIENCY

The charging efficiency (η) of a battery is expressed by the following formula:

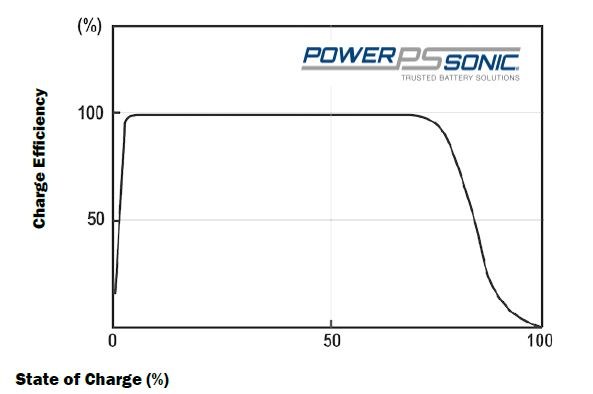

The charging efficiency varies depending upon the state of charge of the battery, temperatures, and charging rates. The below graph illustrates the concept of the state of charge and charging efficiency.

The below graph shows Power Sonic sealed lead acid batteries exhibit very high charging efficiency, even when charged at low charging rates.

It is always important to match your charger to deliver the correct current and voltage for the battery you are charging. For example, you wouldn’t use a 24V charger to charge a 12V battery.

If you have any questions about an existing charger’s capability with one of our products, please give us a call or send us an email. We would be happy to assist you with your charging needs.