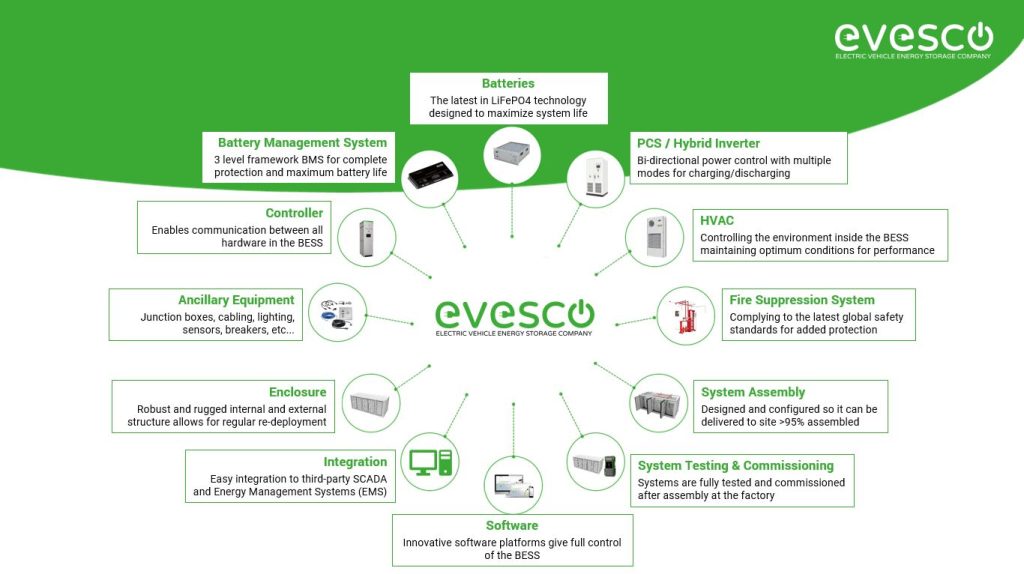

Battery Energy Storage System Components

Battery energy storage plays an essential role in today’s energy mix. As well as commercial and industrial applications, battery energy storage enables electric grids to become more flexible and resilient. It lets grid operators store abundant solar and wind energy for later use. Energy storage professionals, especially developers and EPCs, need a solid understanding of key BESS components and their interactions.

There are many different chemistries of batteries used in energy storage systems. For this guide, we focus on lithium-based systems, which dominate over 90% of the market.

In more detail, let’s look at the critical components of a battery energy storage system (BESS).

Battery System

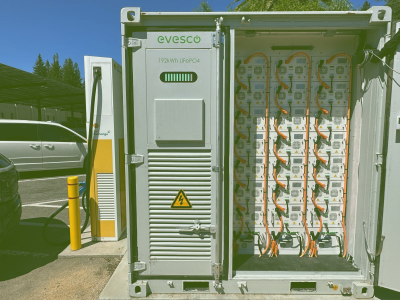

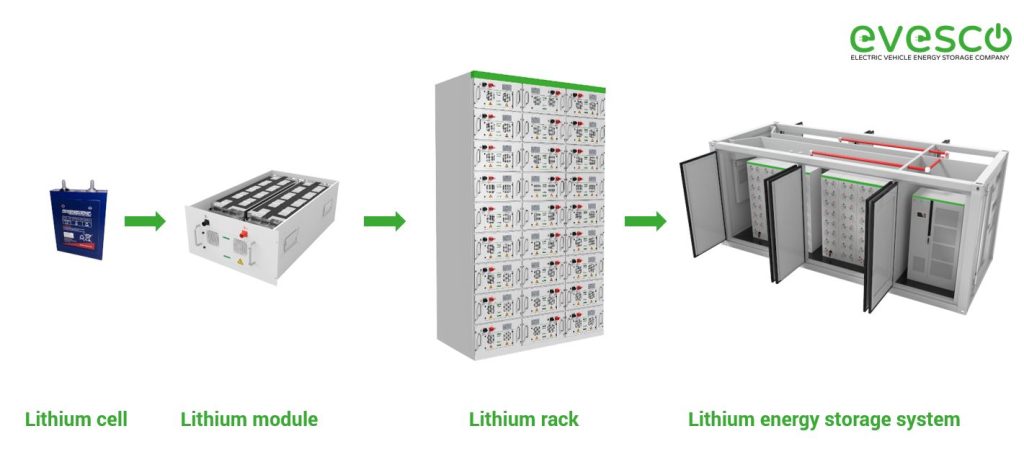

The battery is a crucial component within the BESS; it stores the energy ready to be dispatched when needed. A battery contains lithium cells arranged in series and parallel to form modules, which stack into racks. Racks can connect in series or parallel to meet the BESS voltage and current requirements.

These racks are the building blocks to creating a large, high-power BESS. EVESCO’s battery systems utilize UL1642 cells, UL1973 modules and UL9540A tested racks ensuring both safety and quality.

You can see the build-up of the battery from cell to rack in the picture below.

Battery Management System (BMS)

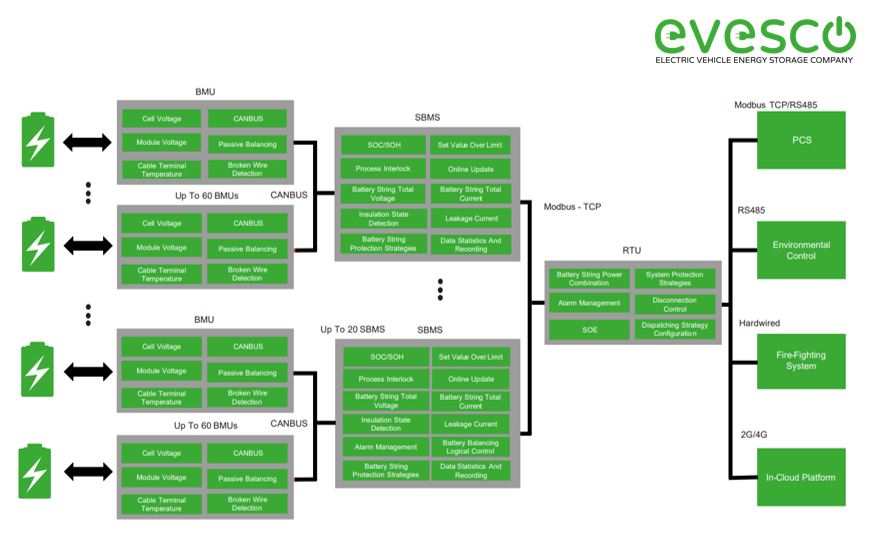

Every lithium-based energy storage system needs a Battery Management System (BMS), which protects the battery by monitoring key parameters like SoC, SoH, voltage, temperature, and current. Advanced BMS, such as EVESCO’s, monitor cells, modules, strings, and the entire system in real time, using algorithms to balance and control the battery, manage thermal conditions, and prevent thermal runaway. A well-designed BMS is essential for battery safety and longevity.

The below picture shows a three-tiered battery management system. The BMS has three levels: a main controller (MBMS), a battery string management module (SBMS), and battery monitoring units (BMUs), with each SBMS supporting up to 60 BMUs.

Power Conversion System (PCS) or Hybrid Inverter

BESS batteries store and deliver DC power, while most loads use AC, requiring a Power Conversion System (PCS) or hybrid inverter. These bidirectional devices convert DC to AC for loads or the grid and AC to DC to charge the battery, enabling charging and discharging. The PCS uses battery status, like SoC and DoD, to manage charge and discharge according to the BESS strategy.

The PCS can provide a fast and accurate power response by communicating with the battery. It can be driven by a pre-set strategy, external signals (on-site meters, etc..), or an Energy Management System (EMS).

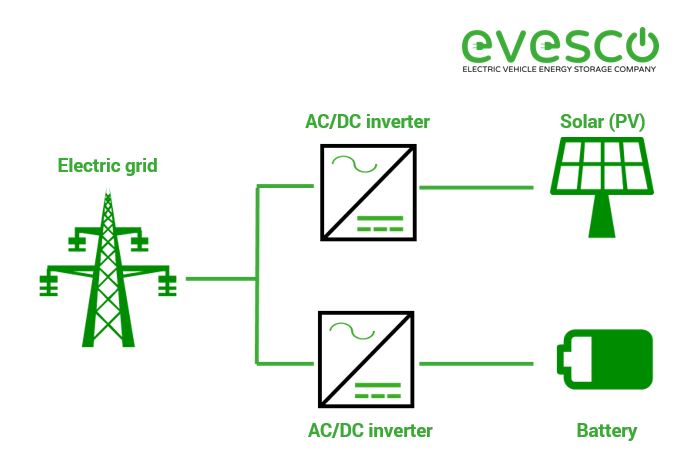

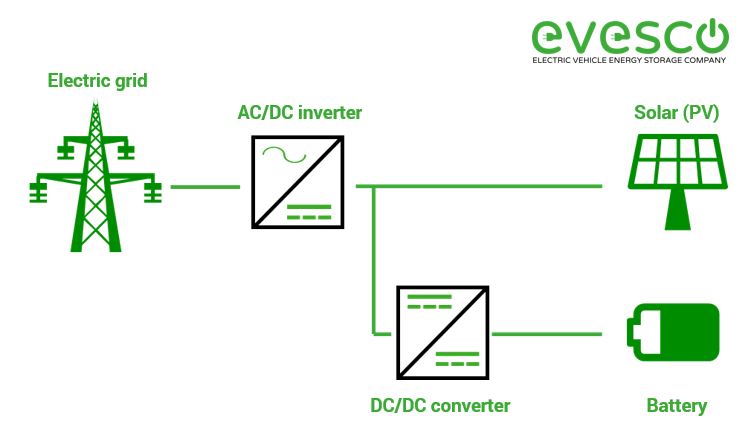

Regarding the PCS, two types of configuration are essential to know. AC-coupled and DC-coupled. For solar + storage applications, there is a choice between the two.

AC-coupled is when the BESS is connected external to the solar PV system on the AC side of the PV inverter. The BESS has its own dedicated inverter connected to the battery.

DC-coupled is when the battery is connected to the same DC bus where the solar PV lands—utilizing a hybrid inverter that is shared between the PV and the BESS.

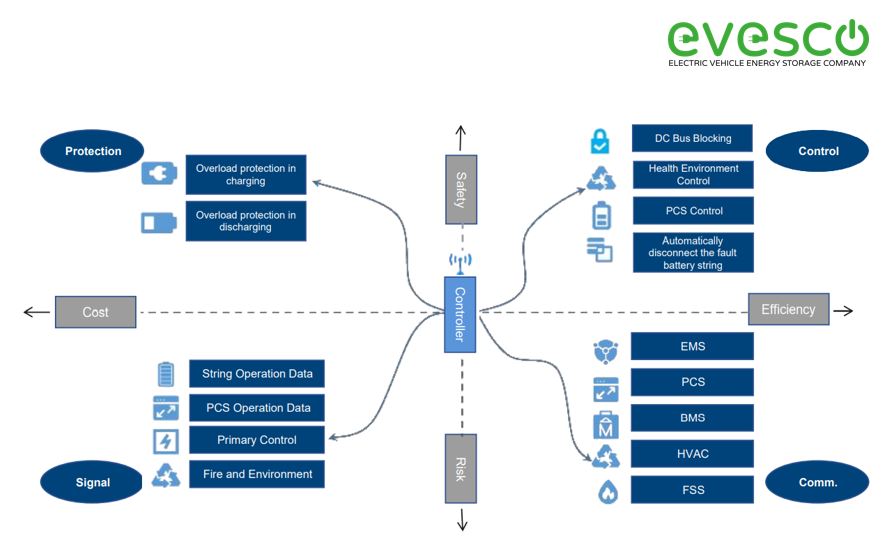

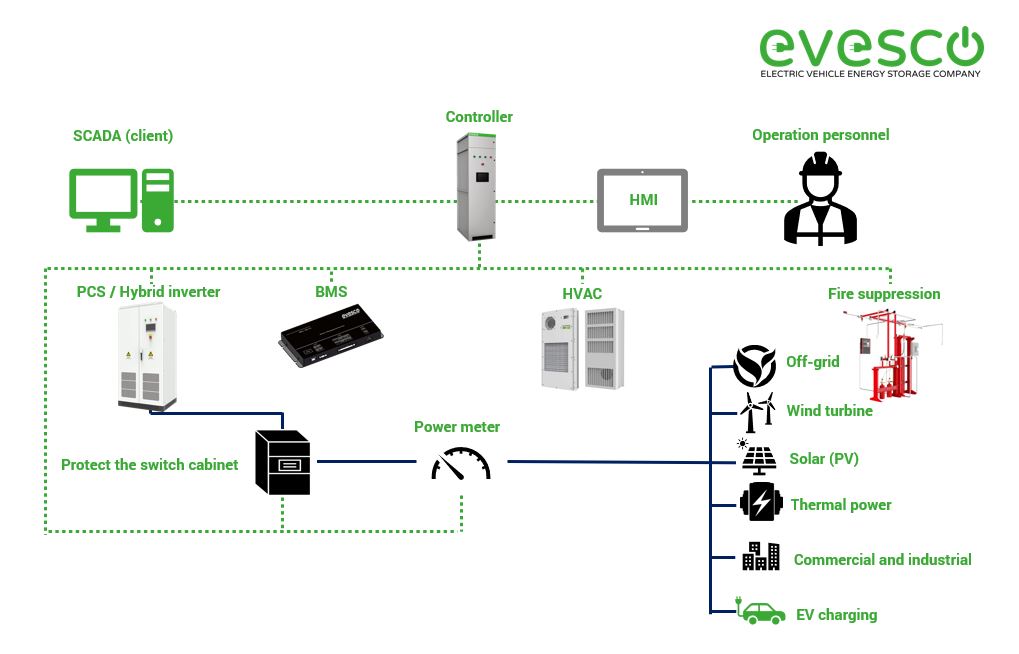

Controller

If the BMS is the brain of the battery system, then the controller is the brain of the entire BESS. It monitors, controls, protects, communicates, and schedules the BESS’s key components, called subsystems. As well as communicating with the components of the energy storage system itself, it can also communicate with external devices such as electricity meters and transformers, ensuring the BESS is operating optimally. The controller has multiple levels of protection, including overload protection in charging and reverse power protection in discharging. The controller can integrate with third-party SCADA and EMS for complete data acquisition and energy management.

HVAC (Heating, ventilation, and air conditioning)

The HVAC system regulates a BESS’s internal temperature, ensuring proper air distribution to extend lithium battery life. Without it, cells can overheat, causing degradation, malfunction, or thermal runaway. Proper HVAC improves performance and longevity.

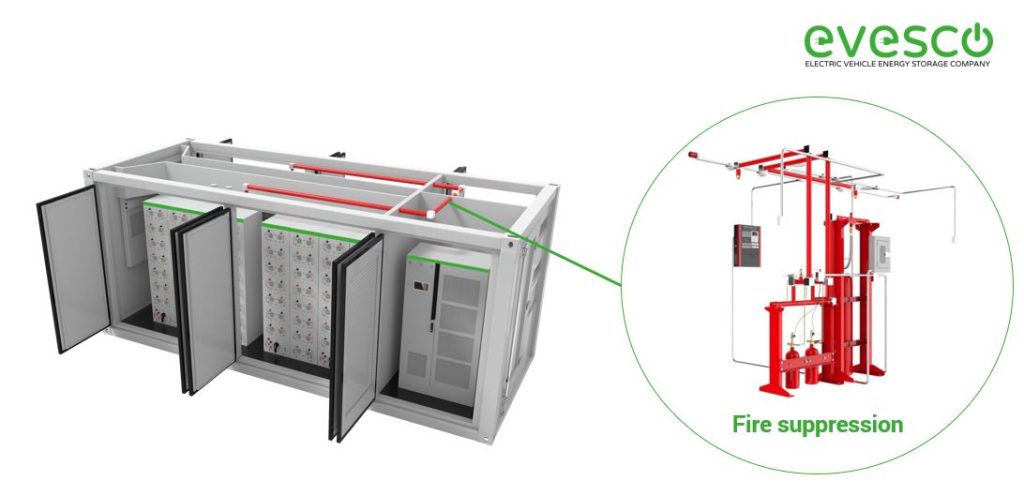

Fire Suppression

A BESS fire suppression system provides an extra safety layer. While the BMS manages battery temperature and shuts down the system if limits are exceeded, it cannot fully prevent thermal runaway. In such cases, the fire suppression system—triggered by gas, smoke, or heat detection—releases an agent to cool and suppress the fire. Systems vary by enclosure size; EVESCO uses Novec1230 or FM-200 to meet international standards.

SCADA (Supervisory Control and Data Acquisition System)

SCADA monitors and controls BESS components via a PLC, interfacing with the BMS, PCS/hybrid inverter, and auxiliary meters. Through the HMI, operators can start/stop the system, manage charging/discharging, and set BMS and auxiliary parameters.

Most BESS can integrate with third-party SCADA systems via different interfaces, including Register Map. It is possible that SCADA can take on the role of an EMS.

Energy Management System (EMS)

The EMS controls and schedules BESS operations, communicating with the PCS/Hybrid Inverter and BMS while considering external data from the grid, PV arrays, and loads. It manages discharge timing for applications like peak shaving or load shifting, optimizes performance and ROI, respects BMS and PCS limits, and collects data for reporting and forecasting.

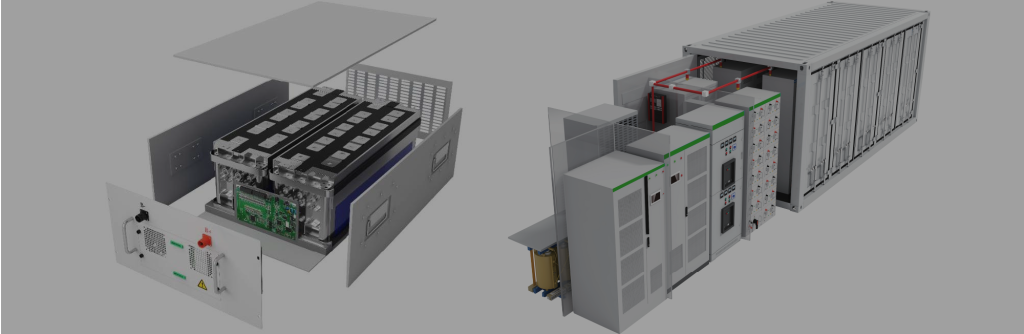

These are the critical components of a battery energy storage system that make them safe, efficient, and valuable. There are several other components and parts to consider with a BESS which can differ between manufacturers. At EVESCO our BESS have rugged containerized enclosures and all 5ft, 10ft, and 20ft systems are fully assembled before shipment, a true plug-and-play solution. Discover how battery energy storage systems works in our dedicated blog.