Flooded Batteries vs. AGM Batteries: Understanding the Differences

When it comes to lead acid batteries, flooded (sometimes called conventional) batteries and AGM (Absorbent Glass Mat) batteries are the two most popular. While both serve the purpose of energy storage, they have distinct differences in terms of construction, maintenance, performance, and applications.

In this blog post, we will explore the key differences between flooded batteries and AGM batteries to help you make an informed choice for your specific needs.

What is the difference between flooded batteries and AGM batteries?

Flooded Batteries

Flooded batteries, also known as wet cell batteries, have a traditional design consisting of lead plates submerged in a liquid electrolyte solution. Separators keep the plates apart, and you need to monitor the electrolyte level and top it with distilled water periodically. They typically require regular maintenance to ensure optimal performance and longevity.

Maintenance activities include checking and maintaining proper fluid levels by adding distilled water as needed, monitoring electrolyte-specific gravity, and periodic equalization charging to address electrolyte stratification.

They require a specific charging regimen to maintain optimal performance. Manufacturers typically express the charging rate for flooded batteries as a percentage of the battery’s capacity (C-rate). The recommended charging rate for flooded batteries is generally less than 10% of their capacity. For example, you should charge a 100Ah flooded battery at 10A or less.

Charging at a slower rate helps ensure a complete and thorough charge, allowing the electrolyte to mix properly and minimizing the risk of stratification. To learn more about C-rates visit battery universities’ article, “What is C-rate?”.

The bulk charge voltage of a 12V flooded lead-acid battery is typically 14.2 volts. During the bulk charging stage, chargers commonly use this voltage and apply a constant current to quickly restore the battery’s energy.

The higher voltage helps facilitate the electrochemical reactions within the battery, allowing for efficient charging. However, it’s important to note that the specific bulk voltage can vary depending on the battery manufacturer, design, and temperature conditions.

The float charge voltage is typically 13.4 volts. During float charging, chargers apply a lower voltage than in the bulk stage to maintain a fully charged battery in standby or maintenance mode.

This voltage level maintains the battery fully charged without overcharging or causing excessive gassing. It compensates for the self-discharge of the battery and any small loads connected to it, ensuring that the battery remains ready for use.

AGM Batteries

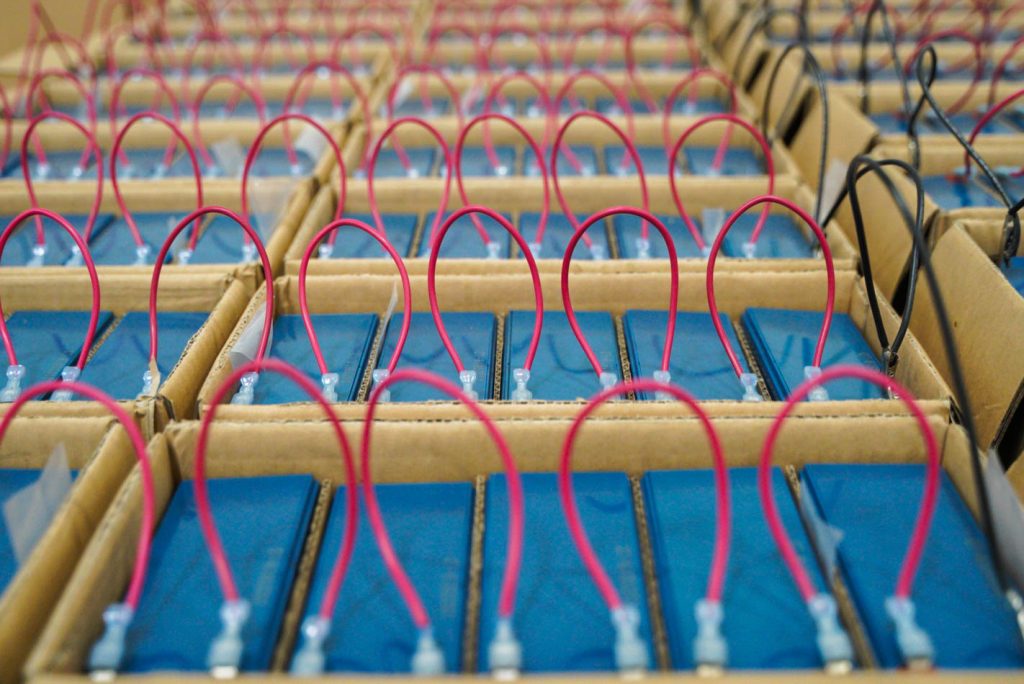

AGM batteries feature a sealed design with a fiberglass mat soaked in electrolyte. The mat sits between the lead plates, effectively immobilizing the electrolyte. AGM batteries do not require the addition of water or electrolyte checks, as the design eliminates the need for maintenance associated with fluid levels.

They have a different charging profile compared to flooded batteries. AGM batteries generally have a more controlled charging approach. The recommended charging rate for AGM batteries is typically around 10-25% of their capacity. Their glass mat design reduces internal resistance and prevents spillage, enabling faster charging and better charge acceptance than flooded batteries. For more information on AGM technology visit our blog post, “The Complete Guide to AGM Batteries”.

The bulk charge voltage of a 12V AGM lead acid battery is typically 14.7 volts, and the float charge is typically 13.8 volts.

When should you use a flooded or AGM battery?

You should choose between AGM and flooded batteries based on the intended application, budget, and charging control.

Assess the specific needs of your application. Flooded batteries are the optimal choice for applications where cost is a primary concern, and regular maintenance can be performed. They can handle higher discharge rates and provide a higher surge current than AGM batteries. This suits high-power applications like automotive starts, off-grid energy, and heavy industrial equipment.

In comparison, AGM batteries are ideal for sealed and maintenance-free setups. AGM batteries have a lower self-discharge rate than flooded batteries. They hold their charge longer, which can be advantageous for applications with infrequent or seasonal use. Additionally, the glass mat separator makes them highly resistant to vibrations and shocks. They are commonly used for deep-cycle RV and boat storage, backup power systems, renewable energy storage, and UPS systems.

Budgetary constraints should also be evaluated. Flooded batteries require periodic maintenance, including topping up electrolyte, equalizing charges, and monitoring specific gravity. This maintenance requirement adds to the overall cost and effort of using flooded batteries. AGM batteries cost more upfront but offer durability and convenience, potentially lowering long-term expenses.

Lastly, the charging control available in your system should be examined. AGM batteries may require more sophisticated charging control to prevent overcharging, while flooded batteries can tolerate higher charging voltages. We recommend our guide to charging sealed lead acid batteries.

Are AGM Batteries safer than flooded?

Flooded batteries can emit gases, including hydrogen and oxygen, during charging and discharging. Adequate ventilation is necessary to prevent the buildup of potentially hazardous gases. Additionally, liquid electrolyte in flooded batteries risks leakage and corrosion if mishandled or poorly maintained.

AGM batteries, on the other hand, feature recombination capabilities, allowing them to recombine the gases produced during charging. This recombination process significantly reduces the emission of hazardous gases, making AGM batteries safer to use in enclosed spaces. The sealed design of AGM batteries also eliminates the risk of electrolyte leakage and corrosion.

Conclusion

Flooded batteries and AGM batteries are two distinct types of lead acid batteries, each with its own set of advantages and considerations. While flooded batteries require regular maintenance and fluid level checks, AGM batteries are maintenance-free. Flooded batteries can handle higher discharge rates, and AGM batteries provide convenience, safety, and better resistance to vibration and shock. Understanding these differences will help you select the appropriate battery type based on your application requirements, maintenance preferences, and safety considerations.